Paper shredder purchasing advice: how to choose the right product

- What You Need to Know

- A document shredder shreds documents in such a way that the information on them is no longer legible.

- The amount of paper that can be shredded within a certain period of time varies considerably depending on the model.

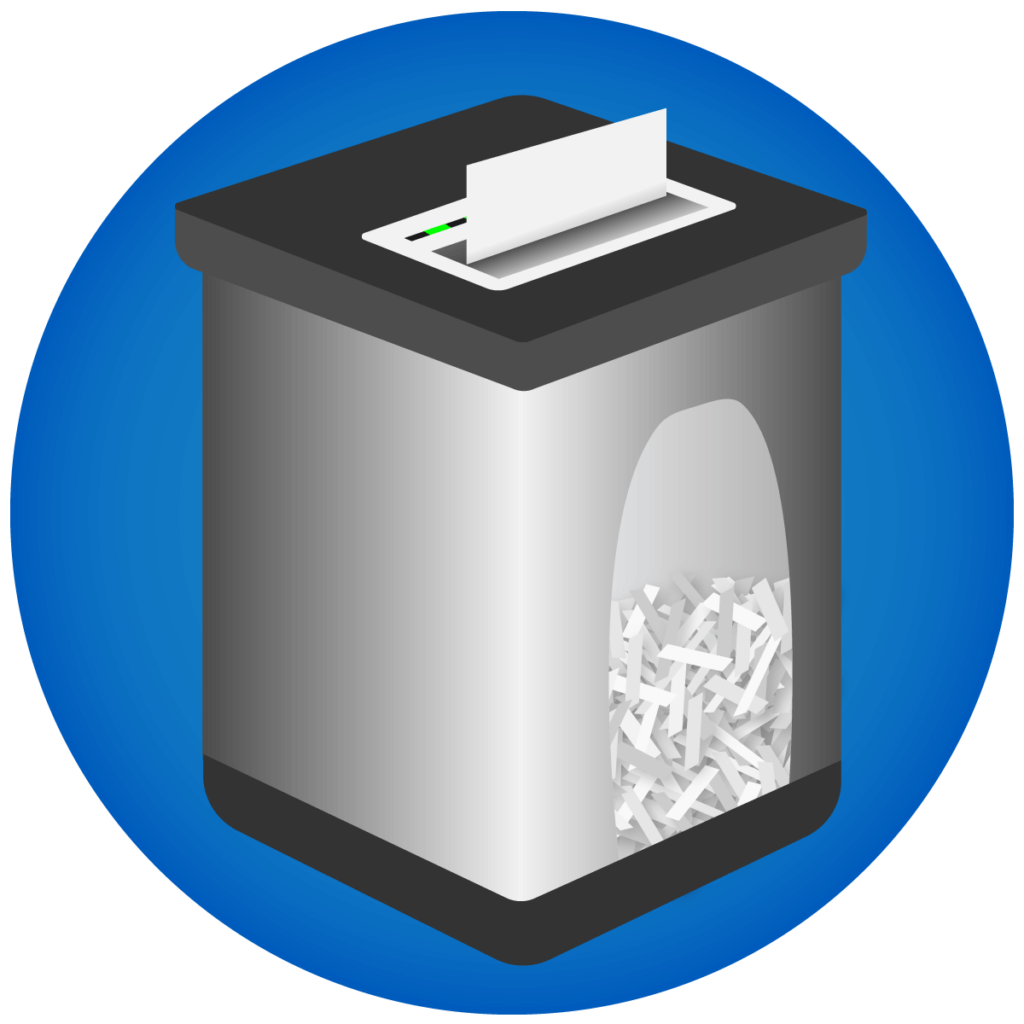

- There are also document shredders with a feeder that automatically feeds in the pages of a stack of paper.

- There are models that can handle different shredding techniques. One of the most popular is the cross-cut.

- The smaller the resulting particles, the less likely it is that the fragments will be successfully reassembled.

- Some devices also destroy paper clips, staples, CDs and bank cards.

- Features such as a narrow feed prevent injuries to fingers.

Why do I need a paper shredder?

A document shredder, also known as a shredder, shredder or paper shredder, cuts paper into strips or pieces and thus makes the information on it illegible. Whether in the private sector, for self-employed persons or in small and medium-sized enterprises: Information on invoices, official documents or project papers must not fall into the wrong hands. Data protection and especially the General Data Protection Regulation (DSGVO), which has been in force since 2018, also require careful handling of company data, addresses, dates of birth and much more. Failure to do so threatens identity theft through the misuse of address, national insurance numbers and dates of birth. If criminals get hold of your credit card, bank and account data, you may be at risk of serious financial damage. Data leaks can also lead to a loss of reputation and declining sales. In principle, companies are obliged to destroy papers containing customer data when they dispose of them. Otherwise, they face severe penalties. Private users do not have to do this, but shredding is still recommended because of the impending dangers.

Mode of operation and shredding

If you carelessly throw away documents or simply tear them up, you risk sensitive data falling into the wrong hands. Generally, more effort is needed to irreversibly destroy the data. In the past, such documents were burned in fire baskets. This entailed the danger that these fires could spread uncontrollably. Moreover, this method is not reliable: If the document does not burn completely, part of the data remains readable.

The first mechanical document shredder consisted of a cutting mechanism driven by a crank. The inventor, Adolf Ehinger, allegedly modelled this on a work tool from Italy: the pasta machine. Both this first version and modern models driven by an electric motor have two shafts facing each other that rotate in different directions. Sharp-edged wheels are arranged on the shafts and interlock. The paper that users feed in at the top of the machine is pulled in and cut into strips by the wheels. The more wheels are mounted on the shaft, the narrower the paper strips become. The length of the strips depends on the length of the sheet fed in.

In addition to the described cutting technique, there are also variants that additionally cut the strips crosswise in order to obtain more paper fragments, to further complicate the reconstruction of the data and thus to take care of higher security requirements. We present the different variants.

What types of cut are there?

Strictly speaking, there are only two different types of cut that document shredders can handle: the strip cut and the particle cut. The first cuts the paper into strips, which can vary in width depending on the cutter. The narrower the strips, the more difficult it is to reassemble them later. Narrower strips therefore increase security. Particle cutting is even safer. Here, the paper is not only cut into strips: Sharp metal edges in the wheels of the cutting unit also ensure that the strips are divided into many small particles, which provides additional security. The particles can only be reassembled with considerable effort, if at all.

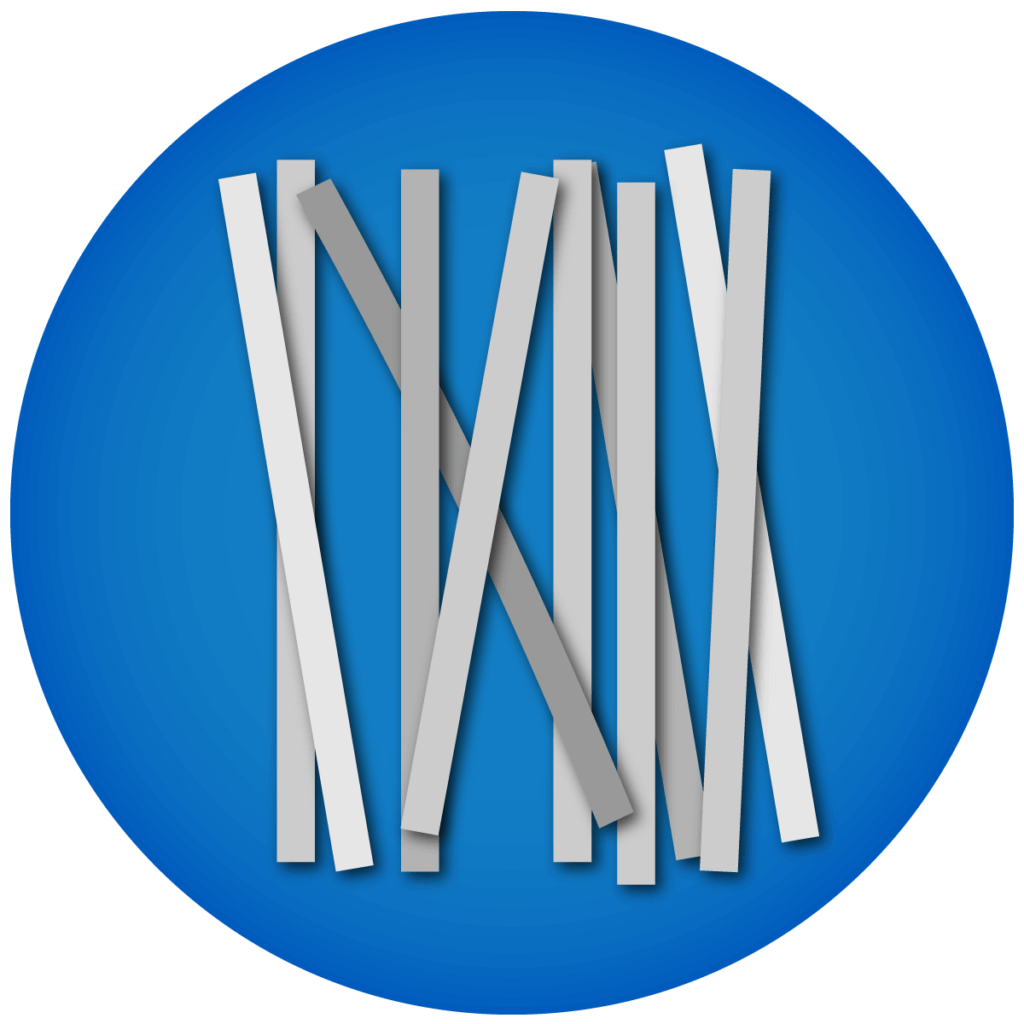

Strip cut

Strip cutting is the simplest technique for shredding documents. Strips of equal width are cut. The width of the strips depends on the number of cutting rollers on the shaft and is between two and twelve millimetres, depending on the security level. The length corresponds to the length of the document. A shred pile consisting of strips has a larger volume than a particle pile. Therefore, the collection basket must be emptied more frequently in the case of strips. With this method, several documents can be fed at the same time, if necessary. Machines using this technique are usually quieter than models that use a different cutting technique.

Pro Points

- Shreds more sheets at the same time than particle cut

- Comparatively low operating noise

Drawbacks

- Wider strips in particular are relatively easy to reassemble

- Larger volume of paper strips requires more frequent emptying of the collection bin

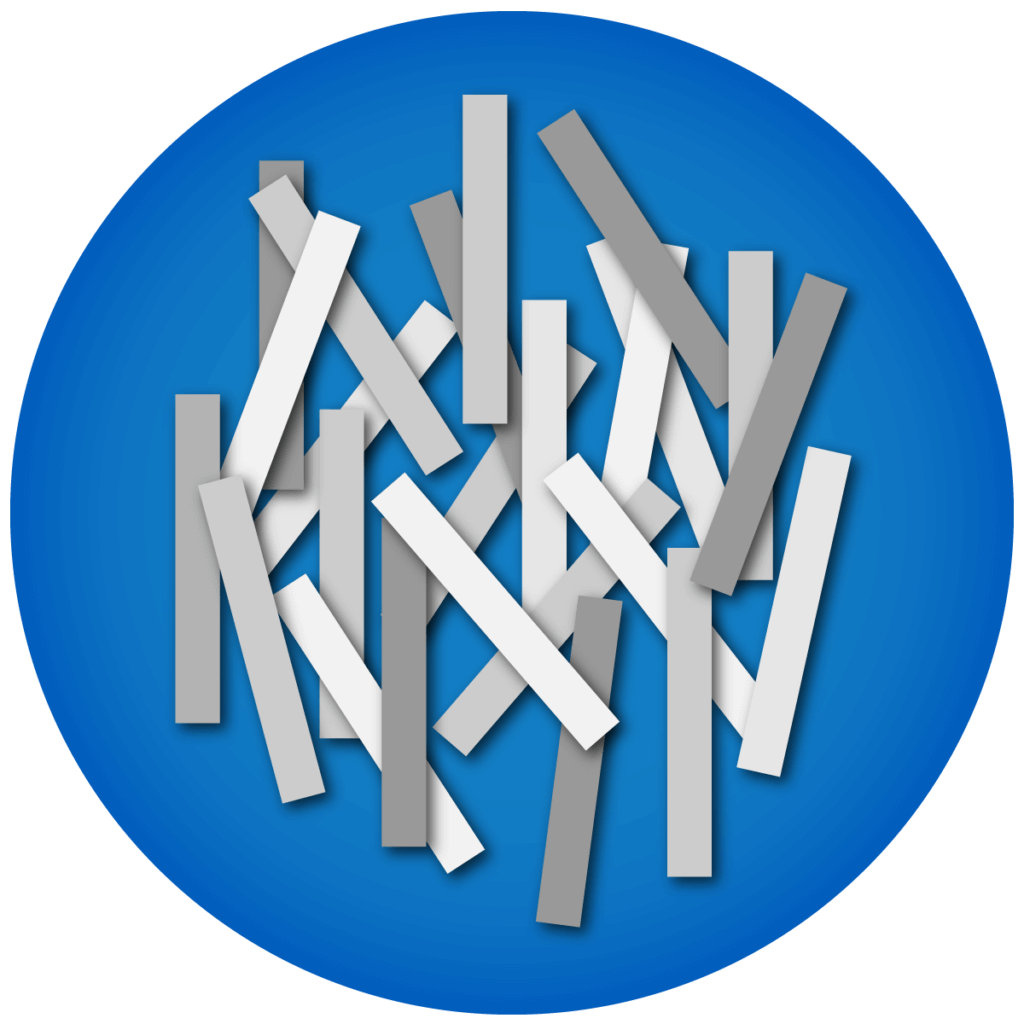

Particle cut

With particle cutting, spikes protruding from the sides of the wheels ensure that the strips are cut transversely. The horizontal cuts ensure a larger number of smaller particles. This makes it more difficult to put them together.

Pro Points

- Greater safety due to smaller particles

- Collecting container has to be emptied less often

Drawbacks

- Number of sheets that can be shredded at the same time is smaller than with strip cut

- Operating noise louder than with particle cut

Cross cut

Cross-cut is an alternative name for particle cut. It is not a shredding method in its own right, but also describes the method in which documents are cut into strips during feeding and the strip is separated into individual particles after a certain length.

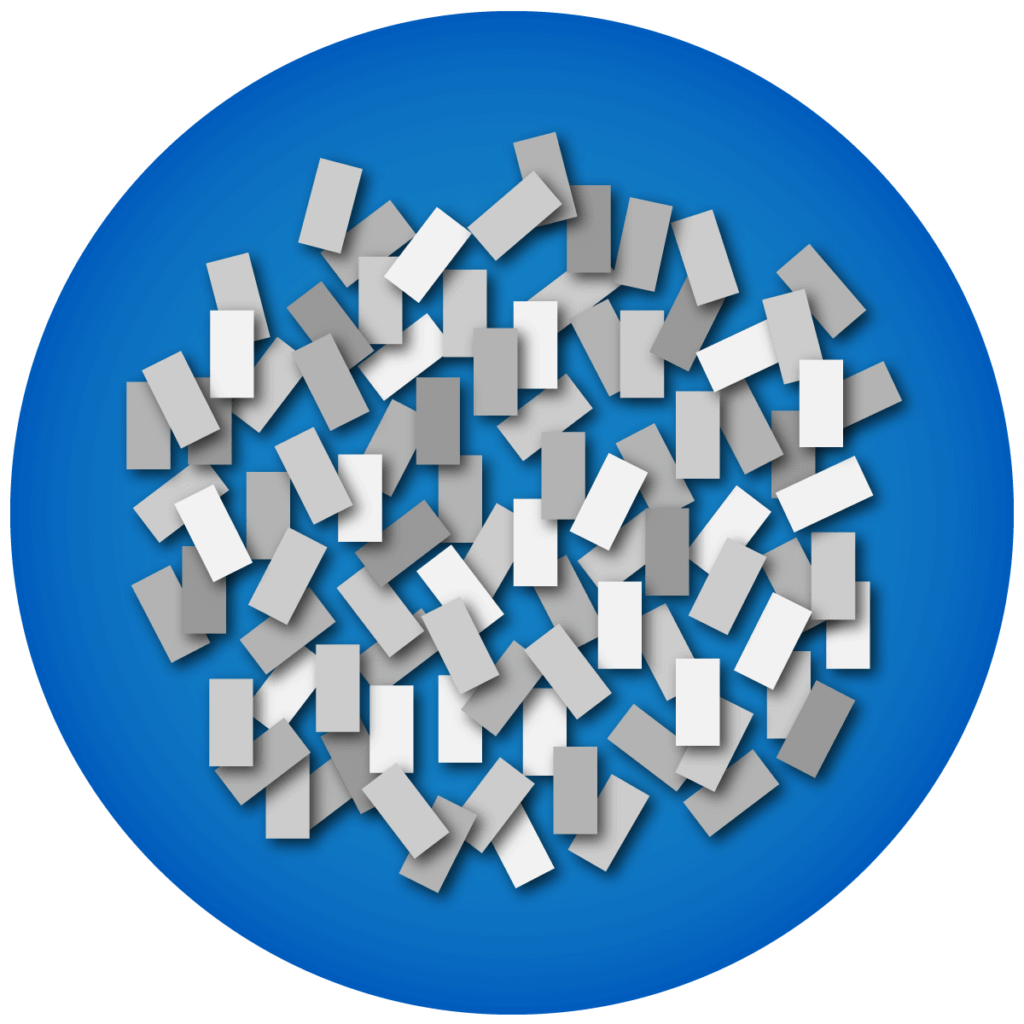

Microcut

Micro-cutting is a special form of particle cutting in which the documents are cut into particularly small particles. The strips are as narrow as possible and are cut in several places, so that many small particles are produced and subsequent reassembly is made difficult to the point of impossibility. This technique is used in areas where data protection is very important, for example by secret services.

The attachment

Most models come as a complete device: it is then usually a cutting unit that is supplied with a matching collection bin. Users feed paper into the top of the machine, which is pulled through the cutter and shredded before falling into the bin. Many models are designed to operate only when the cutter is firmly attached to the receptacle to prevent contact with the dangerous underside of the grinder. When the container is full, the cutting mechanism switches off on many units. After removing the attachment, users must either manually compress the contents by applying pressure or empty the collection basket.

Furthermore, there are a few models on the market that only come with the shredder attachment. Users can then mount these directly above the waste paper bin, for example. Advantage: You do not have to empty the collection bin, the shreds ultimately fall directly into the waste paper bin and are disposed of by the waste collection service when it is emptied. However, since not every shredder model fits on every bin, these shredders usually have a telescopic extension with which the devices can be securely fastened.

Top-mounted unit with door

Another wider variant of larger models for continuous operation are devices that are built into a kind of cabinet. On the top side is the input tray for the paper, and underneath there is also a catch basket, but this is much larger than on the simple models. This is housed behind a flap. Such models are visually less conspicuous. They only work as long as the door on the front is closed. This also prevents accidental contact with the underside of the shredder.

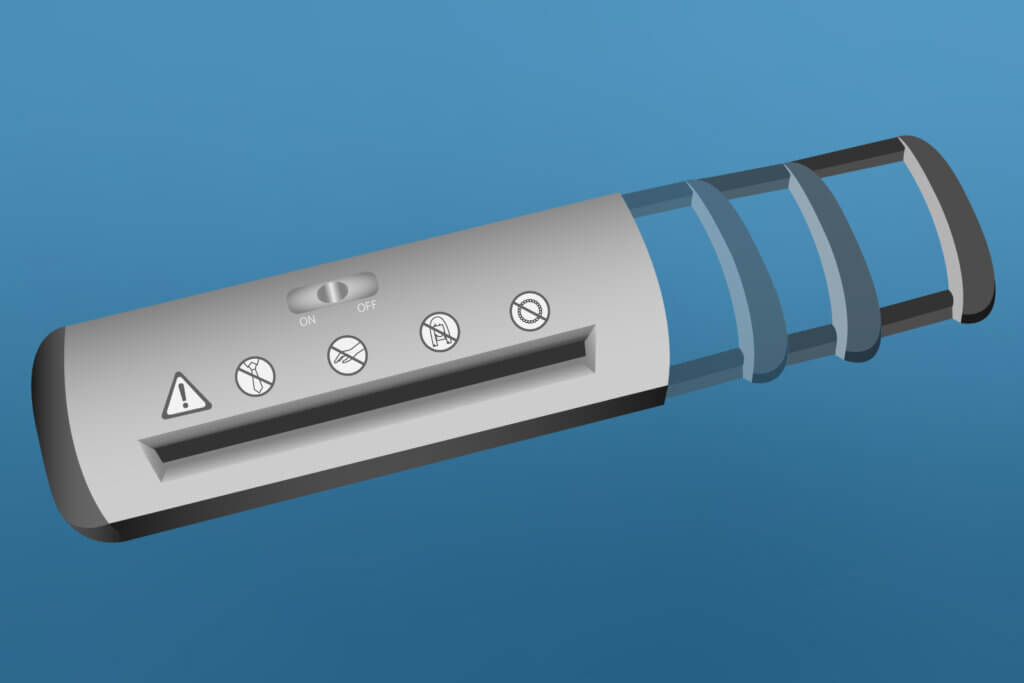

Mini hand shredders

Mini hand shredders are not too widespread. Their dimensions are reminiscent of hair straighteners. Users hold the device with one hand and operate the function button with the other. These shredders only work as long as the button is pressed. This is to prevent accidents if the cutter falls down. Users feed the paper pages with the other hand. As a niche product, such models are suitable for users who very rarely shred a document and also want to save money.

Manual shredders

Manual shredders are devices that users operate manually. They insert the paper into the shredder slot with one hand. With the other hand, they operate the hand crank on the side of the device so that the paper is drawn in and cut into small strips. In the meantime, there are also models that are capable of particle cutting. Such shredders are particularly suitable for smaller quantities of documents. Most models can also handle folded A4 or A5 documents.

However, they are usually not suitable for thicker paper, cardboard or shredding several pages, as this would require too much muscle power. These models have a catch basket for the paper shreds. It would not make sense to place the shredder on top of a waste bin, for example. The crank movements would cause the shredder to move too much, which would pose a risk of injury to the user. In terms of safety, the manual devices do not yet come close to the electric ones, as the latter can produce smaller particles. Nevertheless, they are comparatively cheap to buy, quiet in operation and work without electricity.

Pro Points

- Comparatively low purchase price

- Hardly any noise during operation

- Always ready for use, as they are independent of the power grid

Drawbacks

- Can usually only shred a few sheets at a time

- Cranking quickly tires the hand

- Usually not capable of micro-cutting

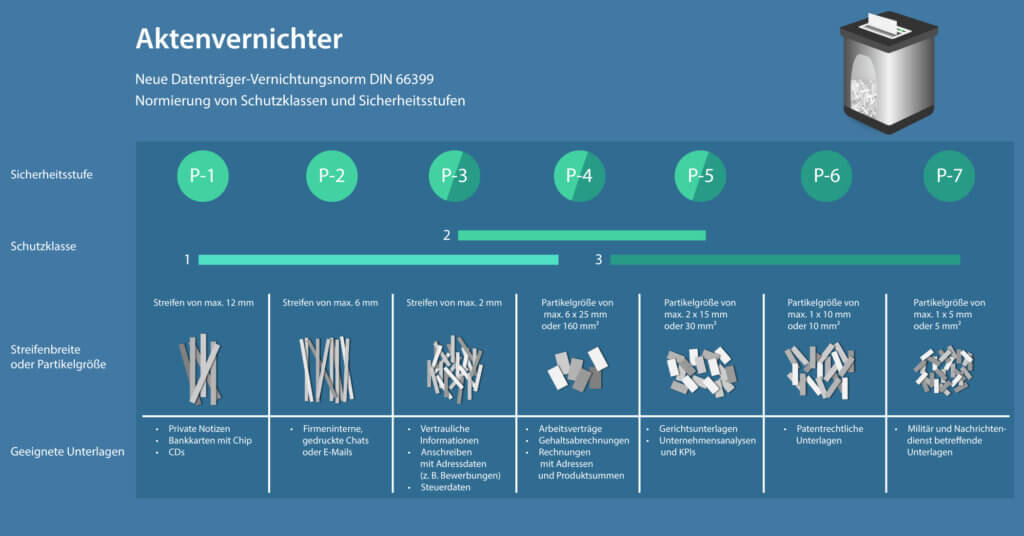

Protection classes and security levels

The destruction of data media, which also includes documents in paper form, has been standardised in DIN 66399 since 2012. It replaced DIN 32757, a standard that manufacturers of small devices for data media destruction used until then.

What does DIN 66399 say?

The new standard enables users who want to destroy their data themselves or hand it over to a specialised company for destruction to determine the protection classes and security levels that meet their requirements and thus to carry out the destruction of the data that meets their needs. In this way, costs are saved for less confidential data. For documents containing very sensitive information, on the other hand, the user can ensure that the data is irretrievably destroyed through small-scale shredding.

In the following, we present the three protection classes defined in the standard and give an overview of the security levels into which these use cases can be classified. Overlaps are possible.

| Protection class | Description | Security level |

| 1 – for internal data and normal security needs | Threat to economic circumstances | 1 – 3 |

| 2 – for confidential data and high security needs | Significant threat to economic circumstances or social standing | 3 – 5 |

| 3 – for particularly confidential data and a very high need for security | Danger to life, limb or freedom | 4 – 7 |

The three protection classes indicate how worthy of protection the data is. The protection level describes how thoroughly the data must be destroyed and how much effort would be required to reassemble the individual parts into a document. In the upper security levels, it is no longer possible to recover the data: by destroying it, it is safe from the eyes of third parties. Data that falls into a certain security class must be destroyed according to the applicable minimum requirements of the associated security level. When buying, you should make sure that the document shredder has a corresponding marking.

For whom is which security level suitable?

Security level 1 cuts comparatively wide strips. Devices at this security level are therefore suitable for non-security-relevant private documents. Level 2 covers written company communication. Confidential information such as address or tax data already requires security level 3. Here, the particle cut is used and documents are much more difficult to reassemble. Security level 4 is suitable for critical papers in the corporate environment, such as employment contracts, salary slips, personnel files or balance sheets. Explosive documents such as process documents require the even higher security level 5. If a lot of money and a potential competitive advantage are at stake, companies are advised to use security level 6 for patent documents, for example. The particles are no more than one by ten millimetres in size and cannot be reassembled. Security level 7 was standardised for military and intelligence service files. The particles produced are twice as small as in the previous level.

Further purchase criteria

In addition to the shred sizes and the corresponding security levels, there are a number of other factors that are important for the purchase decision.

Document size

The vast majority of document shredder models are designed to securely destroy documents in DIN A4 format. Documents of this size are the most common worldwide, except in North America. For larger documents, for example in A3 or A2 format, there are special devices. However, since these are considerably more expensive to purchase, it is advisable for occasional use to fold the documents instead and put them in the shredder. Once folded, a DIN A3 document will then easily fit into the DIN A4 shredder.

Number of sheets

Especially for people who often have to shred large quantities of documents, the question of how many pages they can shred at a time is important. If only a few sheets can be shredded at a time, shredding a stack will take correspondingly longer. Large industrial devices have a paper feed: the sheets of a stack are fed in one after the other, as in a copier, and fed into the cutting unit. Caution: With this procedure, you must ensure that no one removes documents from the stack without authorisation.

What else is shredded?

For many prospective buyers, the decisive factor is which materials can be shredded in addition to paper. Both in the office and in the private sector, the question of whether paper clips and staples can remain in documents without damaging the device during shredding is of interest. Otherwise, they would have to be laboriously removed one by one, which would be very time-consuming for large volumes in the corporate environment. It is also practical if the model can safely destroy CDs and credit cards as well as paper.

Size of the collection bin

The size of the bin determines how often users need to empty it. For private use or in small companies with up to two employees, a volume of 5 to 12 litres is usually sufficient. For daily use in a small department, the volume should be 12 to 40 litres. For open-plan offices, a basket volume of between 40 and 150 litres is recommended for daily use.

Level indicator

Another practical feature is a fill level indicator. If there is only one opaque collection bucket, the user has to lift the cutter from time to time to check whether the bucket needs emptying. If the bucket has a viewing window, the user can see directly whether it needs to be emptied again. Other devices come with sensors: When a certain fill level is reached, an LED lights up to signal the user that he needs to empty the catcher bucket. Models with a strip cut produce a larger filling volume.

Maximum operating time

To prevent damage to the cutting unit’s motor, virtually all units have overheating protection. After a certain operating time, the unit is switched off for a few seconds or minutes until it has cooled down. Units for industrial use have cooling systems and allow longer operation than the inexpensive compact models for private use.

Start-up function

If the model has a shut-off or start-up function, it switches off when there is no new paper to shred. This saves energy and contributes to safety. Most machines only start up when a sheet of paper is in the light barrier of the feeder.

Return

The reverse function is included in almost all devices. If there is an overload, for example because too many sheets were fed into the cutting unit at once, the reverse function ensures that the user can remove the stack and feed it back in decimated.

Safety flap

A safety flap, which makes the paper entry narrower, ensures that fingers or ties do not get into the cutter. The narrow insert allows single sheets to enter the cutter. To shred larger quantities of paper at once, the user has to lift the insert.

Operating noise

Especially if you want to use the machine in an office environment, the operating noise plays a significant role. If the shredder is not located in a separate room, a loud operating noise can quickly become annoying. Many manufacturers advertise that their devices operate quietly. Very few manufacturers give a value in decibels (dB), which makes a real comparison impossible.

Castors

Large appliances with a large collection container take up a comparatively large amount of space and are hardly transportable due to their weight. This is remedied by castors that allow the user to position the device flexibly.

Do I have to maintain the shredder?

The cutting rollers work mechanically and wear out over time. This happens more quickly with cross-cut models than with strip-cut versions. By oiling the cutting mechanism, you prevent it from becoming blurred or the paper from no longer feeding correctly. The operating noise also decreases with regular maintenance. The higher the security level of the machine, the more strain is placed on the cutter. Regular cleaning is recommended for security levels 3 and higher. There are special oils that you can drip or spray into the cutting mechanism. More convenient are special oil-soaked papers that deliver the lubricant directly to the rollers during shredding.

1,256 reviews

1,256 reviews